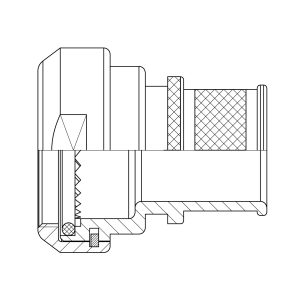

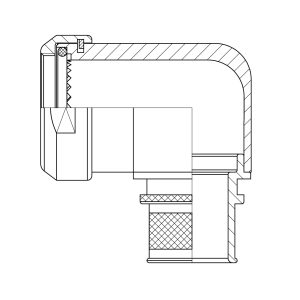

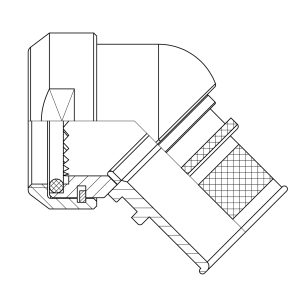

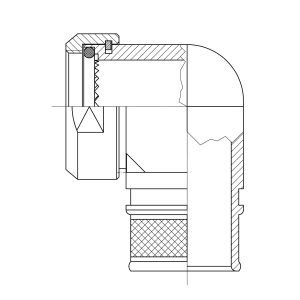

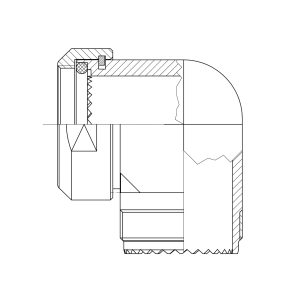

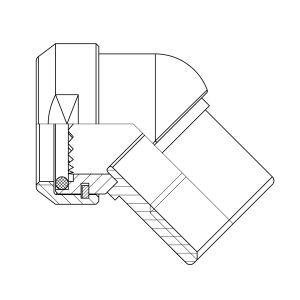

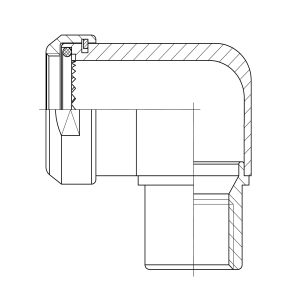

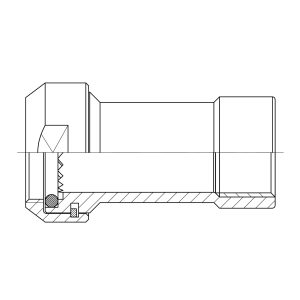

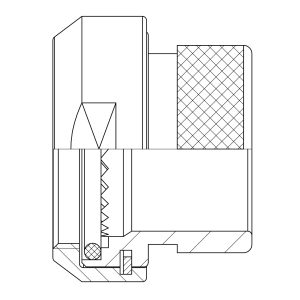

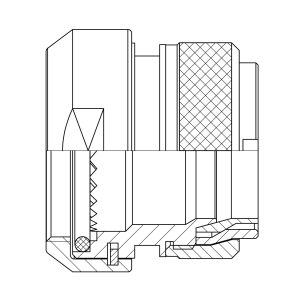

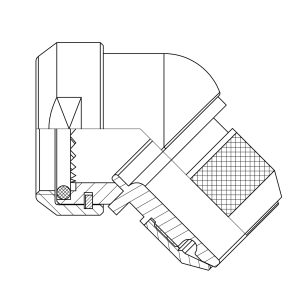

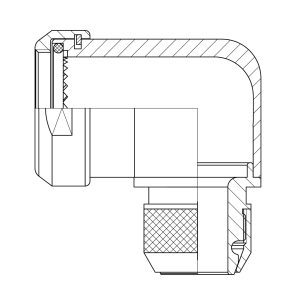

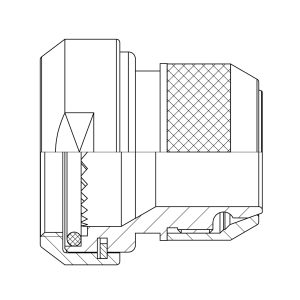

EMCA’s Series A3 backshells deliver high-performance EMC shielding and environmental protection for mission-critical connector assemblies. Available in straight, 45°, and 90° configurations, these backshells are engineered for secure cable management and space-efficient routing in demanding environments. Featuring band termination / constant force spring (CFS) platforms and robust strain relief options, Series A3 supports quick, reliable installations across a wide range of MIL-DTL-38999 Series III and IV connectors. Trusted in aerospace, defence, and high-reliability industrial systems, this series offers proven performance in harsh operating conditions.

| A37-524 A37-525 A37-526 |

4 | J | 08 | KN | ||

|---|---|---|---|---|---|---|

| Basic part number | ||||||

| Shell size code |

ARefer to table A for the required Shell Size code

|

|||||

| Material and plating code |

CRefer to table C for the required Shell Finish code

|

|||||

| Cable entry size |

BRefer to table B for the required Shell Entry Size code

|

|||||

| Option knurled coupling ring |

* Please refer to datasheets for all other backshell types.

All dimensions in mm (inch) unless specified otherwise.

| Shell Size | Shell Size Code |

|---|---|

| 08 (A) | 1 |

| 10 (B) | 2 |

| 12 (C) | 3 |

| 14 (D) | 4 |

| 16 (E) | 5 |

| 18 (F) | 6 |

| 20 (G) | 7 |

| 22 (H) | 8 |

| 24 (J) | 9 |

| Entry Size Code | ØD2 min. | ØD3 max. |

|---|---|---|

| 03 | 4.7 (0.185) | 13.9 (0.547) |

| 04 | 6.3 (0.248) | 13.9 (0.547) |

| 05 | 7.9 (0.311) | 15.5 (0.610) |

| 06 | 9.5 (0.374) | 17.2 (0.677) |

| 07 | 11.1 (0.437) | 18.7 (0.736) |

| 08 | 12.7 (0.500) | 20.3 (0.799) |

| 09 | 14.2 (0.559) | 21.9 (0.862) |

| 10 | 15.8 (0.622) | 23.5 (0.925) |

| 11 | 17.4 (0.685) | 25.1 (0.988) |

| 12 | 19.0 (0.748) | 26.7 (1.051) |

| 13 | 20.6 (0.8115) | 25.1 (0.988) | 14 | 22.2 (0.874) | 29.9 (1.177) |

| 15 | 23.8 (0.937) | 31.5 (1.240) |

| 16 | 25.4 (1.000) | 33.1 (1.303) |

| 17 | 27.0 (1.063) | 34.7 (1.366) |

| 18 | 28.6 (1.126) | 36.3 (1.429) |

| 19 | 30.2 (1.189) | 37.9 (1.492) |

| 20 | 31.8 (1.252) | 39.5 (1.555) |

| 21 | 33.3 (1.311) | 41.1 (1.618) |

| 22 | 35.0 (1.378) | 42.7 (1.681) |

| 23 | 36.5 (1.437) | 44.3 (1.744) |

| 24 | 38.1 (1.500) | 45.9 (1.807) |

| Material & Plating Code | Technical Design | ROHS / REACH Complaint | Electrically Conductive | Salt Spray Resistance (MIL Spec) | Salt Spray Resistance (VG Spec) |

|---|---|---|---|---|---|

| J | Black Hybrid finish

|

Yes | Yes | 500 hrs | 5 days cyclic |

| U | Olive drab Hybrid finish

|

Yes | Yes | 500 hrs | 5 days cyclic |

| 5 | Electroless nickel Base material: Al- alloy. |

Yes | Yes | 48 hrs | 48 hrs |

| 2 | Zinc-Nickel black

|

Yes | Yes | 500 hrs | n.a. |

| 6 | Cadmium olive drab

|

No | Yes | 500 hrs | 5 days cyclic |

| 9 | Marine Bronze Material: CuAl10Ni5Fe4 (CW307G). No additional plating. |

Yes | Yes | n.a. | n.a. |

| 1 | Stainless Steel / passivated |

Yes | Yes | n.a. | n.a. |